Rigorous Quality Control

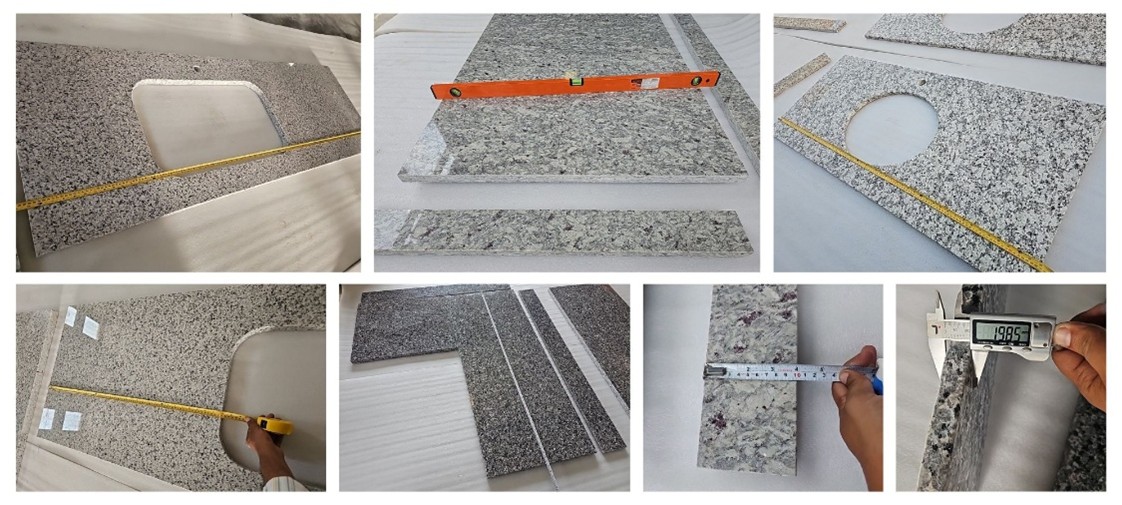

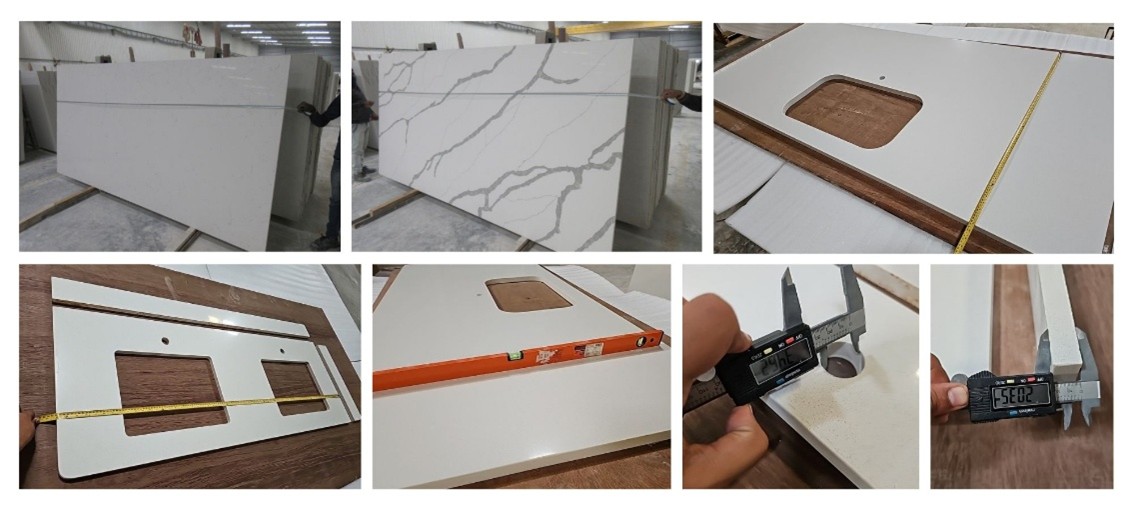

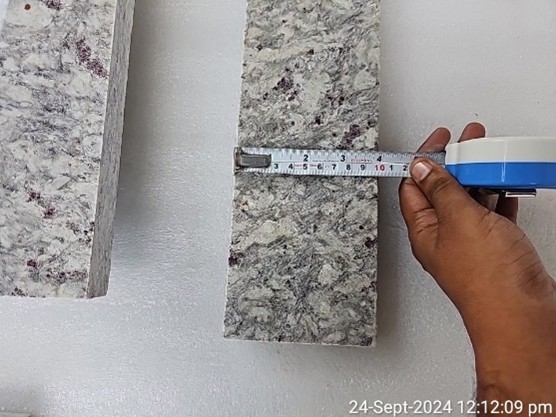

Before any product is approved for shipment, it undergoes comprehensive quality control inspections conducted by our experienced QC team. We verify color accuracy against approved samples, check thickness consistency across the entire surface, examine edge finishes for smoothness and precision, and inspect for any natural variations or imperfections that might affect installation.

Only materials meeting our stringent criteria—and international industry standards—receive final approval. This multi-point inspection process protects your investment and ensures complete satisfaction upon delivery.

Our Inspection Process Includes:

- Dimensional Accuracy: Length, width, and thickness verification with digital calipers.

- Material Inspection: Color consistency, grain structure, and uniform crystal distribution.

- Surface Finish: Gloss meter testing for polish quality, checking for scratches or fissures.

- Cutout Verification: Sink and tap hole measurements against CAD drawings.

- Edge Profiling: Smoothness and shape consistency check.

- Pre-Shipment Report: Detailed documentation and photography for client approval.

Download Catalog

Download Catalog